FENDER-EDGE

PneumaCell

The Last Safety Barrier Between Vessels & Value

FENDER-EDGE

PneumaCell Introduction

No Edge Defined, All Edge Refined.

FENDER-EDGE‘s PneumaCell are expertly designed and manufactured with superior quality, durable materials. We aim to fully unleash pneumatic fender's strength, ensuring it maintains excellent performance even under extreme operating conditions.

ISO 17357-1:2014 JUST BE THE FOUNDATION

ISO 17357-1:2014 JUST BE THE FOUNDATION FENDER-EDGE Pneumatic Fender service include R&D, designing, testing and stringent quality control. All pneumatic fenders design foundation is according to ISO 17357-1:2014 to offer improved durability and safety performance.

WE ARE NOT ONLY ISO 17357-1:2014

In the past 15 years FENDER-EDGE's attention to each detail during the manufacturing process, wherever customer can see or not. Therefore, these fenders has already surpassed ISO17357 in various performance indicators.

These characteristics combine low reaction force, high energy absorption and low hull pressure with excellent berthing capabilities.These fenders adopt solid construction to improved durability and safety. Design service lifespan could reach 15 years.

- Ship to Ship Transfer

- Ship to Shore

- Temporary Berthing

- Port High Tidal Variations

- Submarines

FENDER-EDGE

WHO IS FENDER-EDGE

WHAT “FENDER-EDGE” DO

FENDER-EDGE own over 15 years specific manufacturing and technical experience in the exclusive field of marine fender defense system which is truly rare.

WHY WE ESTABLISH “FENDER-EDGE”

In the past 15 years, we have seen the integration of marine fender market "Complex, Noisy, Involution, Poor Experience and Even Accidents". For us, a group of "Dull People" firmly believe that "Product Strength" is the real essence of business. We always keep our enthusiasm and passion for this field and hope to return business to its essence, so we decide to do something, so FENDER-EDGE born out of necessity...

“FENDER-EDGE” CORE CAPABILITIES

All fenders design and manufacture according to PIANC and OCIMF guidance, but more importantly, we possess a highly experienced technical team. Their extensive on-site experience has given them a deep understanding of the “Weakness” in fenders. They continuously strengthen these “Weakness” through: Fender Structural Design, Rubber Compounding Process, Testing Methods, Production Processes etc. Thus, the true core of our competitive strength comes from this rich on-site experience and expertise.

WHAT IS “FENDER”

Specialize in various berthing fender defense system, ship to ship fender defense system as long as 15 years.

WHAT IS "EDGE"

"NO EDGE DEFINED, ALL EDGE REFINED” is our professionalism..

FENDER-EDGE

PneumaCell Classification

Type I - Chain tire Net fender

D3,300mm*L6,500mm NET TYPE DRAWING

Chain Tire Net (CTN) Fenders (Type I) constructed from a matrix of used tires interconnected by galvanized steel chains arranged in horizontal and vertical networks.The chains are fastened with hammerlocks at each intersection, and connected to the towing lug with shackles.

Type II - Sling Type Fender

D3,300mm*L6,500mm SLING TYPE DRAWING

FENDER-EDGE’s Sling Type Fenders (Type II, without chain tire net.) are expertly manufactured to ISO 17357 standards. This type fender can be slung by chains or wire ropes during operation. These fenders are available across the entire range of sizes.

FENDER-EDGE

To Address Key Challenges in Marine Projects

ISO 17357-1:2014

FENDER-EDGE PneumaCell design and manufacture which truly comply with ISO 17357-1:2014. But not only ISO 17357.

DIFFERENTIATED DESIGN

FENDER-EDGE driving growth through secure, stable and streamlined operations (Technical Drawing Available).

TOTAL QUALITY ASSURANCE

Including timely technical support, replacement and root cause analysis etc. (Post-Delivery Service Certificate Available).

Extended Warranty Protection

FENDER-EDGE PneumaCell include 24-months extended coverage–Ensuring your peace of mind after procurement.

SUPPLY CHAIN VALUE CAPTURE

FENDER-EDGE optimize raw material supply chain, operating instructions, manufacturing methods and process etc. to achieve 15-20% cost efficiency against industry benchmarks.

EXTENDED SERVICE LIFE

FENDER-EDGE PneumaCell design service life is 15 years (According to OCIMF guidelines), which truly on service fender beyond 8 years.

ON-TIME DELIVERY SAFEGUARD

FENDER-EDGE sincerely take full responsibility for products delivery. Daily liquidated damages at 0.3% of contract value.

FULL-LIFECYCLE TECHNICAL PARTNERSHIP

FENDER-EDGE technical personnel account for 60% which have enough ability to provide technical support throughout Specification to Onsite-Operations.

FENDER-EDGE

PneumaCell Superior Construction

6 times SAFETY FACTOR

The ratio of the fender bursting pressure to the initial pressure designed must be at least 6 times to ensure absolute safety.

15 Years Service life

Fender design service life is 15 years comply with the requirements that OCIMF recommended.

24 months Warranty

100% compensation caused by fender quality within 24 months.

0 PRESSURE LOSS

QC department require that no air leakage under initial pressure for 48 hours.

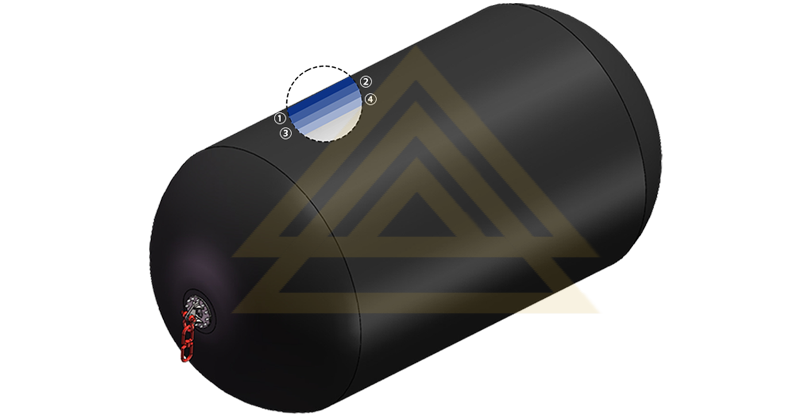

FENDER BODY CONSTRUCTION

① Outer Rubber Layer Part ② Synthetic Tire Cord Layer Part ③ Inner Rubber Layer Part ④ Air Tightness Layer Part

HEAVY-DUTY

The metal parts are firm and reliable, all hot-dip galvanized treatment with highly corrosion-resistant.

Full protection

All chains are covered with high strength rubber sleeve to maximize the safety of fender body.

Anti-detachment safeguard

Chain net end structural parts are optimized in design (the part is easy to detach) to prevent net detachment.

ADVANCED NET DESIGN

The chain net design is carried out based on comprehensive factors such as safety performance, application environment, transportation and cost.

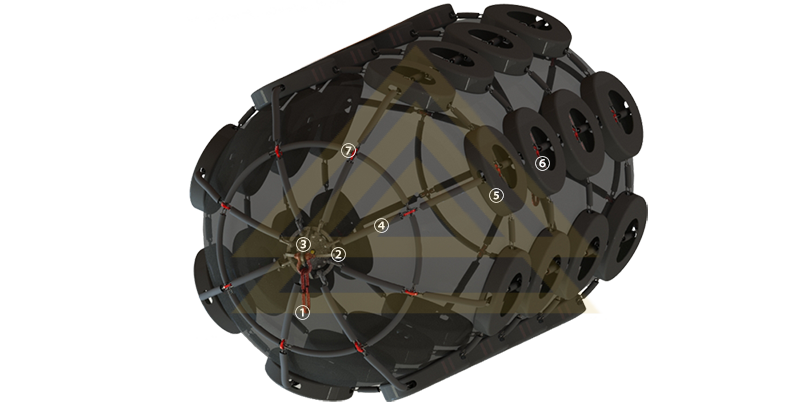

CHAIN TIRE NET CONSTRUCTION

① Swivel ② D Type Shackle ③ Towing Device ④ Rubber Sleeve ⑤ Truck/Aircraft Tire ⑥ Butterfly Shackle ⑦ Chain Net

FENDER-EDGE

PneumaCell Customized

Size Customized

Non-standard fender size customized to meet different application scenarios.

Color Customized

Regular black/navy grey/red/other customized to meet different hull colors.

Initial Pressure Customized

Initial internal pressure Customized: 30kPa/50kPa/80kPa/100kPa etc.

Structural Device Customized

Fender end structural device design to realize multiple functions such as water injection, pressure release, pressure measurement and inflation.

CTN Customized

CTN (Chain Tire Net) Customized: Metal parts, truck/aircraft tire, chain net etc.

Hydro Pneumatic Fender

Customized pneumatic fender apply for submarine berthing.

FENDER-EDGE

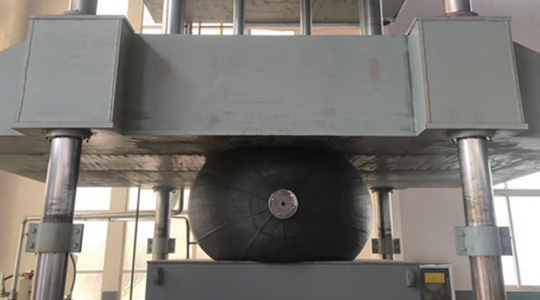

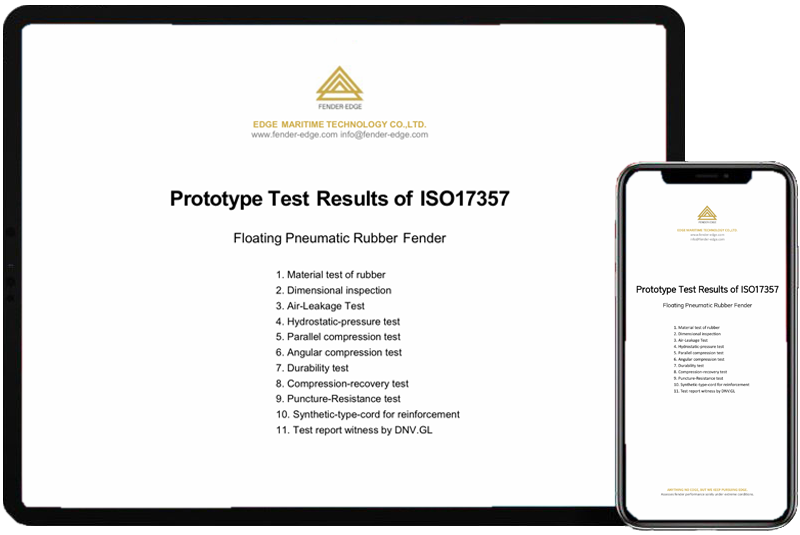

ISO 17357-1:2014 Prototype Test

WHAT IS ISO 17357-1:2014

ISO 17357-1:2014 is an international standard that specifies the requirements for pneumatic fenders used in marine applications, particularly for ship-to-ship and ship-to-quay operations. It defines the design, performance, and testing criteria for these fenders, ensuring that they provide adequate protection to ships and infrastructure during docking or mooring, especially in rough conditions.

The standard outlines the necessary specifications for fender size, pressure, and durability, aiming toprevent damage during interactions between vessels and berthing points.

Material test of rubber

Physical properties of outer rubber, Physical properties of inner rubber etc.

Dimensional inspection

Fender length:+10%,-5%, Fender diameter:+10%,-5%.

Air-Leakage Test

The air-leakage test shall be conducted on all fenders at initial pressure for more than 30 min, and the test results shall confirm that there is no air leakage

Hydrostatic-pressure test

The increase in diameter and length shall be obtained by measuring the distance of two points marked circumferentially and longitudinally at 10kPa pressure on fender’s body. The distance between the two points shall be larger than one-fifth of the fender’s diameter. The temporary elongation shall be measured after maintaining the rated hydrostatic pressure for 10 min.

Parallel compression test

The test shall be repeated twice with an interval of 5 min between the two tests. The energy absorption and the reaction force shall be obtained from the mean value of the two test records.

Angular compression test

The test shall be repeated twice with an interval of 5 min between the two tests.The energy absorption and the reaction force shall be obtained from the mean value of the two lest records.

Durability test

The test shall comprise 3000 repetitive cycles of parallel compression from the original diameter to the maximum deflection. After 3000 cycles, there is no cracks and other harmful detects on any part of the fender. No reduction of the GEA shall be accepted.

Compression-recovery test

After compression of the fender to the guaranteed energy-absorption deflection, the fender shall be kept in this compressed state for 1 min, then the load shall be released instantaneously.

Puncture-Resistance test

The test conducted in accordance with the static puncture test (CBR test) in ISO 12236.

Confirmation of synthetic-type-cord for reinforcement

Synthetic type cord density, tensile strength etc.

Test report witness by DNV.GL

Test report list.

FENDER-EDGE

PneumaCell Related Resources

FENDER-EDGE PneumaCell Brochure

FENDER-EDGE‘s PneumaCell is expertly designed and manufactured with superior quality, durable materials. We aim to fully unleash pneumatic fender's strength, ensuring it maintains excellent performance even under extreme operating conditions.

FENDER-EDGE Pneumatic Fender White Paper

The white paper details the FENDER-EDGE PneumaCell's comprehensive performance, how we comply with ISO 17357 standard, and compares key manufacturing processes and configurations for pneumatic fenders—analyzing their impact on performance, safety, and service life.

FENDER-EDGE PneumaCell Performance Test Report

This report provides a detailed breakdown of PneumaCell (Pneumatic Fender) performance test into three parts. These three parts directly determine the safety performance, enabling users to intuitively and logically understand the superiority of PneumaCell.

FENDER-EDGE PneumaCell Post-Delivery Service Manual

FENDER-EDGE PneumaCell comes with a 24-month warranty. This manual details the associated warranty coverage. Additionally, FENDER-EDGE provides full life-cycle technical support and services, including Root Cause Analysis (RCA), to safeguard customer interests and reduce after-sales costs.

FENDER-EDGE PneumaCell Operation Manual

This manual details handling, storage, installation and maintenance of PneumaCell. FENDER-EDGE’s PneumaCell is almost maintenance-free. They are ideal partner for permanent and semi-permanent fender solutions for ports as well as ship-to-ship transfers.

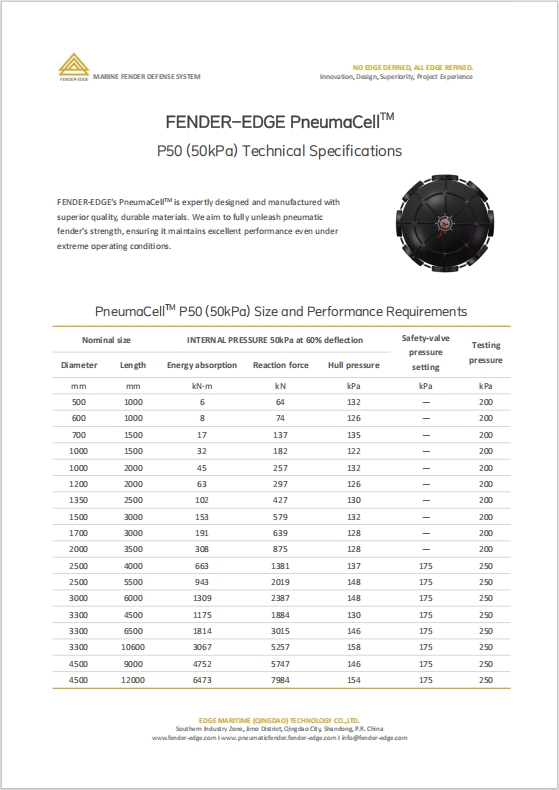

FENDER-EDGE PneumaCell Technical Parameter

PneumaCell P50 (50kPa) & PneumaCell P80 (80kPa) Size, Performance, Pressure Requirements.

FENDER-EDGE

Contact FENDER-EDGE Team

MANUFACTURING CENTER

Southern Industry Zone, Jimo District, Qingdao City, Shandong, P.R. China

+86 187 5421 1053

Take the first step, we

will take care for the rest